AGCULTURE announces the launch of Geysir, the first energy-saving single glass with high hemispherical light transmission. “With this product, we continue to pursue our vision of empowering growers to produce healthier crops and increase yields while reducing their use of carbon-based energy resources,” says the team at AGCULTURE.

European growers have suffered greatly from last year’s unprecedented gas price hikes. “As experts in the field will attest, anyway that can be found to save on gas consumption really makes a difference these days. But even before these recent challenges, the horticulture industry had already embraced the move towards more sustainable solutions in order to reduce the amount of CO2 emitted for each kilogram of crop produced”, the team at AGCULTURE says. “Geysir has been designed in part to address these global concerns.”

Geysir is clear float glass treated with a low-emissivity (low-E) pyrolytic coating applied immediately after the float glass has been produced. “As a result, this online coating is thoroughly integrated into the glass surface, delivering superb durability. The glass is then vacuum coated with two durable AR coatings to boost PAR and hemispherical light transmission to levels comparable with current horticultural glass products. Both low-E and AR coatings are considered Class A coatings under European standards, attesting to their long-lasting performance.”

Immediate energy savings

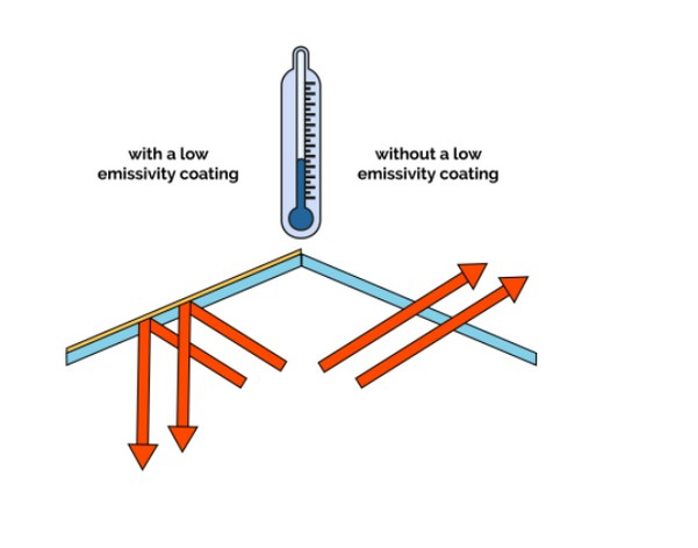

The durable low-E coating applied to the outer surface of Geysir reflects far-infrared heat back into the greenhouse, ensuring the glass acts as a fully transparent single-layer energy screen. The result: up to 22.2% lower gas consumption per year based on the latest WUR research funded by Dutch greenhouse horticulture organization ‘Kas als Energiebron’*. Thanks to this energy-saving coating, the glass lets maximum light into the greenhouse, especially in winter when natural light is scarce and when using additional mechanical energy-saving screens would reduce the amount of natural light entering the greenhouse, thus requiring greater use of assimilation lamps and consequently increasing electricity consumption. In other words, with Geysir, growers can use fewer hours of screening and boost the amount of natural light in their greenhouses during the time of year when natural light is limited.

Crop and leaf temperature control means healthier crops

The amount of energy lost by crops and leaves depends on sky conditions. When the sky is clear, and the sun is shining, the sky temperature is low. Crops sense this and start to lose energy, leading to lower leaf temperatures and a higher chance of condensation forming on the leaves. The result is a higher likelihood of bacteria and disease. Low-E Geysir glass reflects the radiative heat loss of crops when the sky is cold but clear. On the other hand, cloudy skies mean the sky temperature is high, and as a result, crops do not lose much energy since the clouds themselves act as a low-E coating. In that case, there is less need for low-E glass, and if it rains and the glass becomes wet on the outside, then the low-E effect is reduced (at a time when it is not needed anyway).

Less condensation, higher relative humidity, indirect energy savings

Due to the position of the low-E coating on the outside of the greenhouse, all the heat reflected by the coating passes through the glass twice, resulting in a higher glass temperature. This means less condensation on the inner surface of the glass and a subsequent increase in relative humidity (RH). Interestingly, the increase in RH does not lead to more condensation on the leaves due to the fact that the leaf temperature has also increased. Moreover, a higher RH leads to more latent heat and a more stable air temperature, giving the grower a better opportunity to more easily and efficiently control the climate inside the greenhouse. Higher RH also means that the heat pumps can consume less gas, delivering secondary savings for growers. These are all benefits of deploying Geysir.

No trapped heat in summer

One of the potential problems with low-E coated glass in summer is that it causes heat to be trapped. Why? Because solar radiation converts to far infrared after re-emission inside the greenhouse, and since the low-E coating reflects all far infrared radiation, this could cause heat to be trapped inside. If such cases, growers may need to ventilate their greenhouses more, which can lead to CO2 loss and a subsequent reduction in crop yield. However, if Geysir is whitewashed, then it will lose its low-E effect as long as the whitewash is on the glass. This is what most growers do in summer, and as a result, whitewashed Geysir acts like normal glass, and heat is no longer trapped. Of course, once the whitewash is removed, the glass regains its low-E functionality and is ready for the upcoming cold season. The high durability of both coatings ensures steady performance whenever whitewash is applied and removed.

Ideal for cold climates

In cold climates like northern Europe and America, the cold season is longer than the hot season, requiring greater energy consumption by greenhouses compared to other parts of the world. On the other hand, the crop’s market value is much higher during the cold season compared to the hot season, driven by higher operating costs during winter in cold climates. This, along with current gas prices, is making life more difficult for growers. As mentioned above, Geysir can increase the greenhouse yields in winter while also saving significant amounts of energy. WUR is currently running an experiment with Geysir in Bleiswijk (in the Netherlands) with a view to demonstrating all the abovementioned benefits of this glass. The experiment will end in December, but promising results have already been observed.